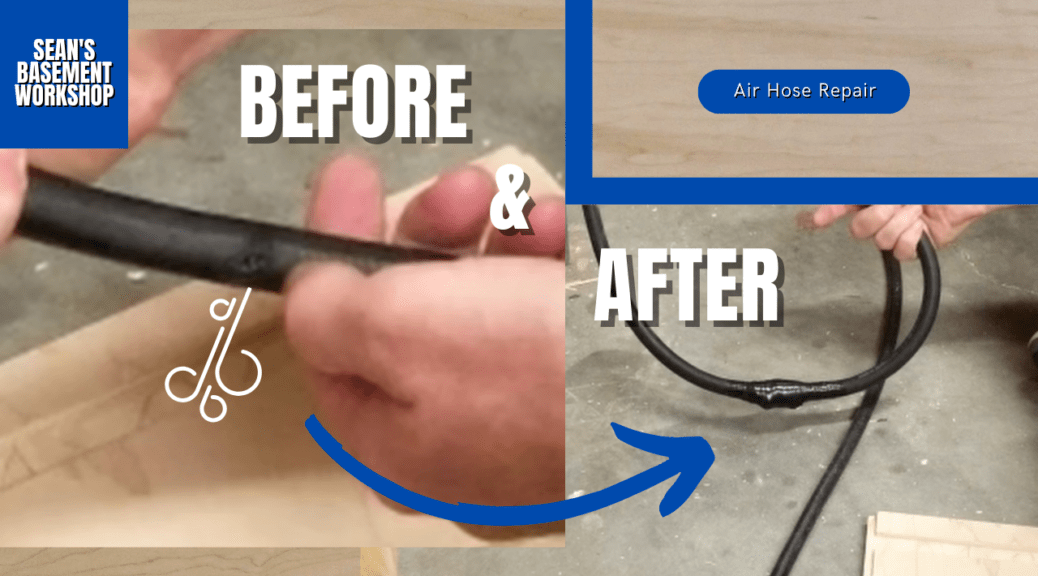

Learn how to master the art of repairing air hose blowouts swiftly with these 5 essential techniques. Never worry about downtime again!

Introduction

In the world of pneumatic tools and machinery, air hose blowouts can spell disaster, causing unexpected downtime and potentially hazardous situations. However, mastering the art of repairing air hose blowouts swiftly is not only possible but essential for maintaining productivity and safety in various industries. In this comprehensive guide, I will delve into the techniques and strategies to quickly and effectively address air hose blowouts, ensuring minimal disruption and maximum efficiency.

Master the Art of Repairing Air Hose Blowouts Swiftly!

Air hose blowouts can occur unexpectedly, often at the most inconvenient times which just happened to me in my case. Whether you’re on a construction site, in a woodworking shop, in an automotive garage, or operating heavy machinery, knowing how to handle these situations promptly can make all the difference.

Understanding Air Hose Blowouts

Before diving into repair techniques, it’s crucial to understand what causes air hose blowouts. These can stem from factors such as excessive pressure, wear and tear, improper maintenance, or manufacturing quality and defects. By identifying the root cause, you can implement preventive measures to minimize the risk of blowouts in the future. However, sometimes they are just unavoidable.

Essential Tools for Quick Repairs

To swiftly address air hose blowouts, you’ll need a few essential tools readily available. These may include hose clamps, couplings, duct tape, hose repair kits, and a sharp utility knife. Having these tools on hand allows you to respond promptly to blowouts without wasting precious time searching for supplies. I’ve taken the liberty of listing these below in the Equipment Section.

Technique 1: Temporary Patching

When faced with a sudden air hose blowout, temporary patching can provide a quick fix to resume operations temporarily. Using duct tape or a hose repair kit, carefully seal the damaged area, ensuring a tight and secure fit. While this solution may not be permanent, it buys valuable time until a more thorough repair can be conducted.

Technique 2: Coupling Replacement

For more extensive damage or when temporary patching is insufficient, replacing the damaged section of the hose with a coupling is a viable solution. Using a sharp utility knife, carefully cut out the damaged portion, ensuring clean and even cuts. Then, attach the coupling to both ends of the hose, securing them tightly with hose clamps. This method restores the integrity of the hose, allowing for continued use with minimal downtime. This is the method that I further talk about below and demonstrate in the video.

Technique 3: Professional Repair Services

In cases of severe damage or when DIY solutions prove inadequate, seeking professional repair services is recommended. Experienced technicians possess the expertise and specialized equipment to assess the extent of damage accurately and perform comprehensive repairs. While this option may incur additional costs, it ensures the safety and reliability of the repaired hose, reducing the risk of future blowouts. When using this technique you have to weigh the cost-benefit of the repair versus buying a completely new hose.

Technique 4: Preventive Maintenance Practices

Prevention is always better than cure when it comes to air hose blowouts. Implementing regular maintenance practices, such as inspecting hoses for signs of wear, checking for leaks, and replacing worn components, can significantly reduce the likelihood of blowouts occurring. Additionally, maintaining optimal air pressure levels and using quality hoses and fittings contribute to overall system reliability and safety. However, if you do follow these preventative measures, some air hoses are just low quality and do not last under pressure (pun intended).

Technique 5: Employee Training and Awareness

Empowering employees with the knowledge and skills to recognize and respond to air hose blowouts is critical for workplace safety. Providing comprehensive training on proper hose handling, maintenance procedures, and emergency protocols equips workers to handle unexpected situations confidently. Moreover, fostering a culture of safety awareness promotes proactive measures to prevent accidents and minimize downtime.

Technique 2: Coupling Replacement Demonstrated

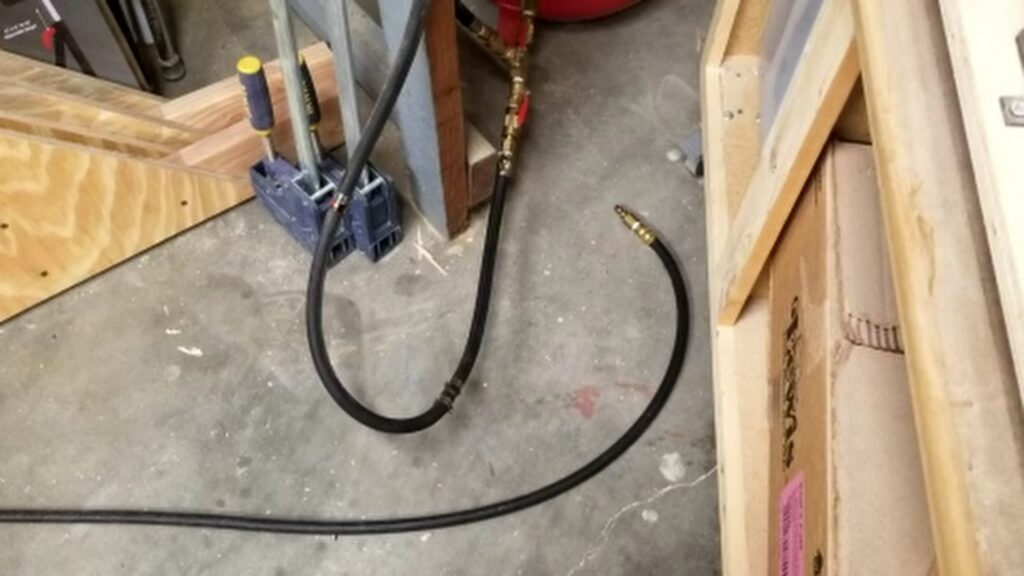

As I stated above, this is the technique that I chose to use. Follow along as I repair an air hose that blew out in my wood shop while I was using it. I determined the quality of the rubber used in the line was not stellar and thus in the future I did have additional blowouts. Eventually, I chose to replace my entire air distribution with copper lines only using air hoses at the termination ends of copper with quick coupler connections.

The first step is to identify where the hole blew. As you can see here it was a pretty good hole.

The next step is to cut out the bad section using a utility knife. Be sure to cut enough back from the hole to ensure you’re getting where the hose blew through the inner layers and not just where it blew out the outer rubber layer.

Then using an air hose splicing kit I put a hose clamp on both sides of the cut followed by shoving the barbed brass fitting inside the air hose. Once it was fully seated I slid the clamps onto the fitting tightening them down.

Once the coupler is pushed all the way on both sides, slide the hose clamps in place and tighten them down to get a good seal.

Next, I pressure test the light to ensure there are no leaks. If there tighten up the clamps more and see if that stops. If it doesn’t, you may have to figure out how it is leaking and cut the slice bigger if or readjust the coupler.

Next, I’m going to conceal the hose clamps so they do not get snagged on anything. To do so I take a plain plastic grocery bag and wrap it around the hose and clamps. Then I take some electrical tape and wrap the hose and bag with it creating a smoother surface only leaving a bulge in the line.

After that, it’s pretty much using the air hose back like normal. Below is the end result and the hose lasted a few more months but eventually blew holes in other locations. As a result, that is why I replaced this feed line with a copper line to my air regulators.

FAQs (Frequently Asked Questions)

- How common are air hose blowouts? Air hose blowouts can occur with varying frequency depending on factors such as usage intensity, environmental conditions, and maintenance practices. While they may not be daily occurrences, being prepared to address them swiftly is essential for mitigating potential risks.

- Can air hose blowouts be prevented entirely? While it’s challenging to eliminate the possibility of air hose blowouts, proactive maintenance, and safety measures can significantly reduce their occurrence. Regular inspections, proper maintenance, and employee training are pivotal in preventing blowouts and ensuring workplace safety.

- What are the potential consequences of ignoring air hose blowouts? Ignoring air hose blowouts can lead to serious consequences, including equipment damage, production delays, and safety hazards. Uncontrolled releases of compressed air pose risks of injury to personnel and damage to surrounding equipment, underscoring the importance of swift and effective repairs.

- Are there specific industries more prone to air hose blowouts? Industries that rely heavily on pneumatic tools and machinery, such as construction, manufacturing, automotive repair, and mining, are more susceptible to air hose blowouts due to the intensive use of compressed air systems. However, proper maintenance and safety protocols can mitigate these risks across various sectors.

- How long does it typically take to repair an air hose blowout? The repair time for an air hose blowout can vary depending on factors such as the extent of damage, availability of replacement parts, and repair techniques employed. Temporary fixes may take minutes to implement, while more comprehensive repairs or professional services may require hours or longer, depending on the complexity of the damage.

- What should I do if I encounter an air hose blowout while operating machinery? In the event of an air hose blowout, prioritize safety by immediately shutting off the air supply and safely securing any affected equipment. Follow established emergency protocols, such as evacuating the area if necessary, and proceed with repair or replacement procedures once conditions are safe.

Conclusion

Mastering the art of repairing air hose blowouts swiftly is essential for maintaining productivity, safety, and operational efficiency in various industries. By understanding the causes of blowouts, equipping oneself with the necessary tools and techniques, and prioritizing preventive maintenance and employee training, businesses can minimize downtime and ensure workplace safety. Remember, swift action and proactive measures are key to mitigating the risks associated with air hose blowouts.

Equipment and Materials

I hope you find this helpful video useful and can use some of the tips presented. Feel free to leave any comments, suggestions, or experiences you have had below.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a different purchase from Amazon, you can also use the storewide link.