What does a washing machine inlet valve look like from the inside out? Well, let us tear down this old valve I just replaced on my washing machine. We’ll take a look at how simple this device is and how it works.

First, let me explain what the washing machine inlet valve is. A washing machine inlet valve is a valve or pair of valves that control the water flow from your water taps to the inside of the washer. Older style valves were single meaning that one valve, one water inlet (cold or hot). Newer models however are a dual valve body meaning two separate valves on one assembly (cold and hot). The valve I’m tearing down is a dual model.

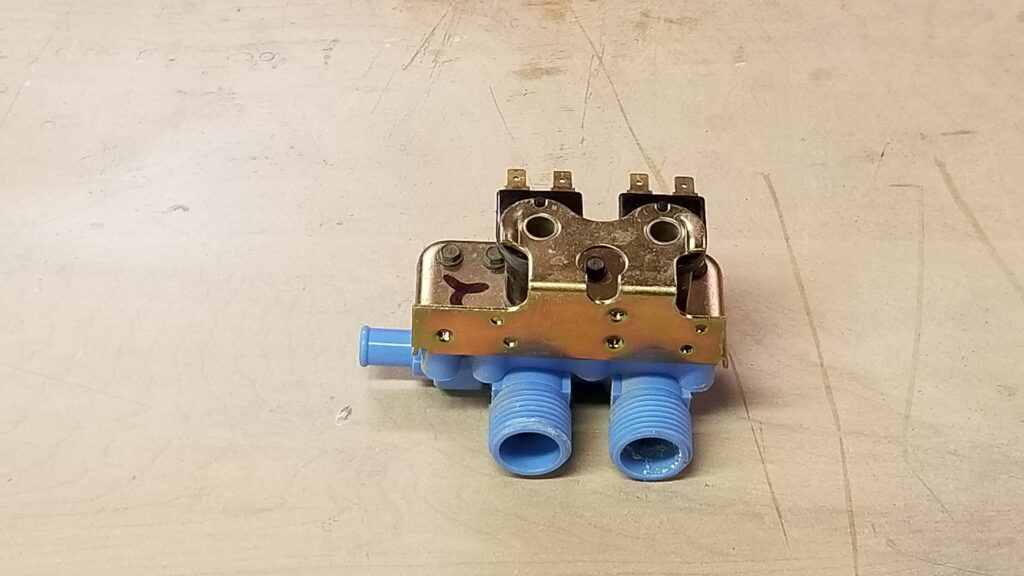

The pictures below show where and what this valve looks like. This valve is located internally near the top side of the washer and if in use, has the cold and hot water hose lines connected to it. These hoses could be rubber, reinforced rubber, or stainless steel braided. I created a different article where I talk about the importance of replacing these hoses. It can be found here.

In this image, we see the protective screens that help filter out larger sediment that can come in from your water lines. Finer stuff can make it through the screens larger will not. You can see here my hot water side (right) is really bad from all the mineral build-up.

Unfortunately, I have this problem with anything that uses hot water from sink faucets, washing machines to dishwashers. I wish I could find something that I could attach to the outlet on my hot water heater that would allow filtering and a central location to clean it out. My cold water is not like this so I’m not worried about an entire house system, just the hot water supply. I even regularly flush out my hot water tank and mineral fragments come out each time. There’s just something about the heating process with our public water that seems to do this for me.

Let us start the disassembly by removing the metal bracket’s retaining screws with a socket bit. I use my Kobalt drill with my DeWalt extension. I know I mix match brands but at the time I couldn’t beat the price of the Kobalt drill when I needed a new one as my old 12v DeWalt battery pack was giving out.

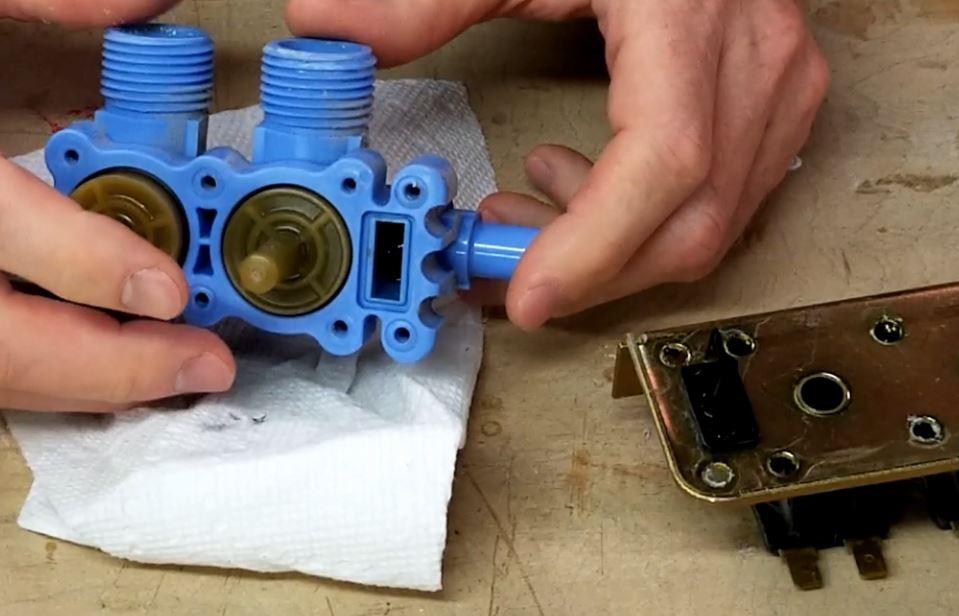

Once I get all the screws out I was able to separate the metal sub-assembly from the plastic body. This exposed the solenoid actuators that control the water flow.

Inside of the plastic body, underneath the actuators is where all the action happens. In the image below A is the water inlet from the supply hoses. When the solenoid activates, it lefts a little rubber plunger up inside the actuator body that allows water to flow from A to B. B is the water exit from this valve which flows into a single channel on the backside of this image. The water at this point flows towards C which a little rubber flap, seen in the above image on the metal assembly, mixes the hot and cold water. From there it flows out the little nozzle where my finger is above.

Here is what the underside of the actuator looks like where you can see the rubber seal that is attached to a metal rod via the little blue connector. The metal rod slides up and down in the plastic actuator shaft as the solenoid turns on or off.

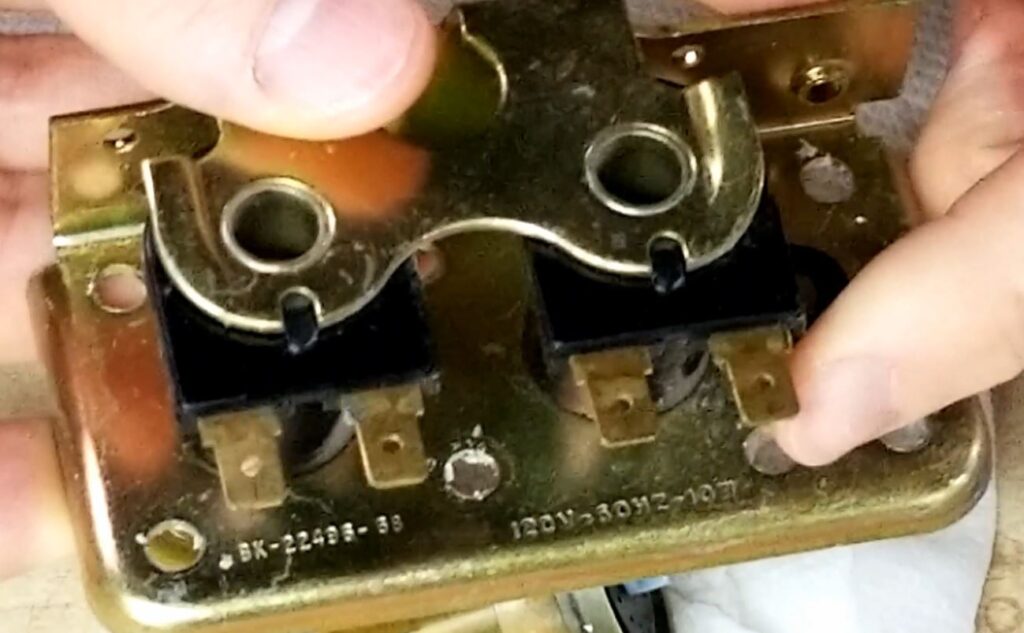

The metal assembly holds two 120v solenoids. When power is applied to the solenoid, it causes the metal shaft in the actuator to slide upward allowing the rubber seal to move away from the water inlet hole thus allowing water to flow to the exit hole.

Below are several images of what the complete valve looks like after disassembly with all the parts.

One thing I thought about after taking this apart is what if you run the water in the opposite direction? Could use clamp a water hose to the water exit on the valve and connect garden hoses to the water supply line connections. Then supply 120v to the solenoids in a timed fashion in such a way that you end up with a timed irrigation system? This is just a thought of mine and I have not tried it. A word of caution though, if you do attempt such a thing, remember electricity and water DO NOT mix. Therefore, you need to make sure you’re taking all precautions to isolate the power to the solenoids and the water in such a way they will not come in contact with each other. I’d also recommend ensuring the power source is connected to a GFCI circuit too!

As always if you have any questions or comments post them below or on my YouTube video comments section and I’ll do my best to respond.

I’ve included a few links to the equipment I used and Amazon Links below for the equipment and materials I used.

Equipment and Materials

- Craftsman Screwdriver Set, Assorted, 25-Piece

- Water Inlet Valve Assembly

- Kobalt 24-Volt Max Lithium Ion (Li-ion) 1/2-in Cordless Brushless Drill

I hope you find this video useful and can use some of the tips presented. Feel free to leave any comments, suggestions, or experiences you have had below.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a different purchase from Amazon, you can also use the storewide link.