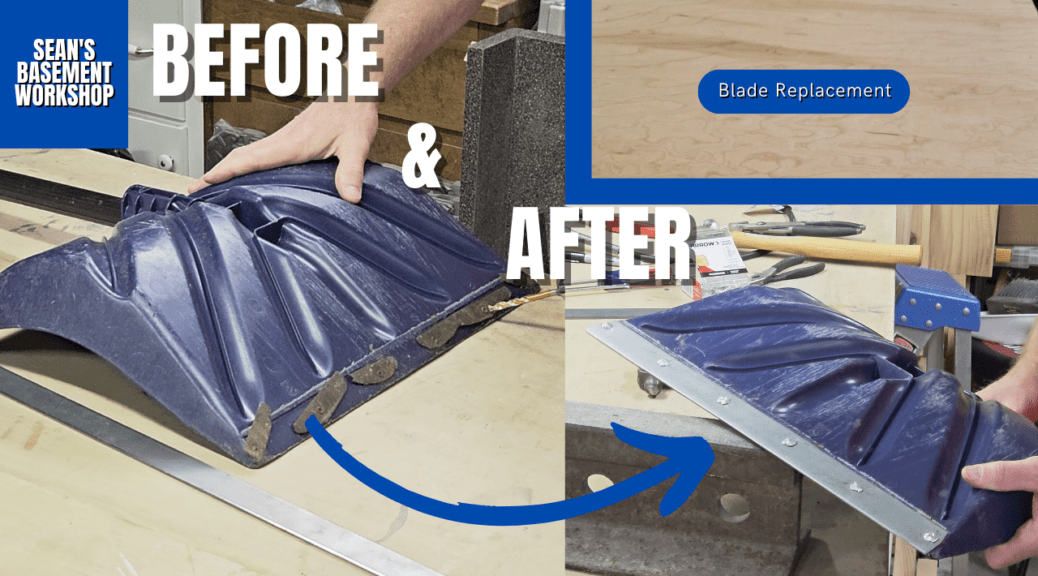

So you get your first snow (or any snow of the season) and you pull out your trusty snow shovel and start trying to shovel snow only to find out that the metal blade on the bottom is worn out, digging in and/or preventing you from getting a nice clean scrape across the pavement you’re trying to shovel. What do you do? Go buy another one – sure, that’s option if the stores haven’t sold out already. There is another one though that I will show you that will save you money and allow you to reuse that old tired shovel rather than pitching it in the trash.

You’ll need a few tools to this job and one you might need to borrow from a friend if you don’t have one or just bite the bullet and buy one.

You’ll need these tools

- Corded or cordless drill

- Drill bit about the same size as the rivets holding on the old steal blade

- Marking tool – marker or pencil

- Some sort of lubricant

- Tape Measure

- Hacksaw or another tool to cut off some new steel

- Rivet Gun and appropriately sized rivets

- Hammer

- Flat Screwdriver

- Flat Steel bar (approximately the size width of where the old blade was)

- Metal File (optional)

Okay I know that sounds daunting but it’s really not. The rivet gun is the only specialty tool you’ll need. The rest you may already have except the steel bar and the rivets.

My first step was to remove the old worn out blade by drilling the old rivets out. I did this with my Kobalt cordless drill using 3/16″ drill bit. This allowed me to remove part of the rivet which then allowed me to use a screwdriver to pop the old rivet stud though the shovel.

The next step in this process was to measure the width and the length of where the old blade was. I determined for my shovel a 1 1/4″ flat steel bar would work as long as it was at least 18 inches long. I headed down to my local home center and picked up some 1/8″ x 1 1/4″ x 36″ flat steel bar and some 3/16″ rivets. These were the same size as what was in there.

Once all the old blade was removed I placed the new flat steel bar on the shovel and used a sharpie to mark the correct length and the angle the ends would need to be cut at.

Now, depending on what you have to cut steel with (hacksaw, angle grinder or Dremel), you’ll need to cut the steel bar to match the lines you drew in the previous step. I am fortunately to have a Dremel so I used it with a cutoff wheel to cut through it.

Once I had the metal cut to length I put it back on the shovel and marked where the previous rivet holes were in the shovel. Now, off to my drill press to drill the holes using the same 3/16″ bit because that is the size of the rivets. Now, you can drill these by hand using your drill but you should clamp down this metal. Even on a drill press you should clamp down this metal to prevent the bit from catching it and spinning it around like a lawn mower blade.

Before and during the drill process of each hole you’ll want to put a drop or so of lubricant down. I used 3-in-ONE Oil but you can use any oil. The purpose is to keep the bit from over heating which will greatly dull and wear out your bit.

Once all the holes are drill, clean off the metal shavings and oil. I used a paper towel and just wiped it off into the trash.

Now you’ll wan to line up one of the holes in the shovel and steel bar. Load the rivet gun by sticking the small nail like piece of the rivet into the gun. Then shove that fat end of the rivet through the hole making sure it goes all the way through the steel bar and the shove hole. Then just start squeezing the rivet gun handle until you hear a loud pop. The nail like end will break off and you’ll have set your first rivet. Do this same thing to the rest of the holes.

When done you’ll probably notice a flat button like piece of metal on one side of the shovel and a little knob on the other side. Now, these little knobs will have to be dealt with as they will not allow the shovel to slide smoothly on the surface.

To do this, I ended up slicing these in half and then flatting them out with a ball peen hammer but any hammer will do. You’ll need a hard surface to be on the other side of where you are hitting otherwise you can damage the surface you’re hitting on. For me, my “anvil” is just small section of railroad track that I just happen to have laying around. However, you can use an anvil, a vice or anything else that is strong enough to allow the hammer to smash the metal rivet flat.

Once I flattened all the rivets flat I decided to take a file and file down the corners. These corners were quite sharp for me and I didn’t want them to snag on anything. Rounding over these corners was the last step for me.

Now my new flat steel blade sticks out from the shovel end about 1/8″ but this will keep the plastic from wearing away on the concrete I need to shovel. In addition, this extra part of the steel makes a great hard edge to vertically hit into any ice or packed snow breaking it up quickly.

Equipment and Materials

I hope you find this helpful video useful and can use some of the tips presented. Feel free to leave any comments, suggestions, or experiences you have had below.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a different purchase from Amazon, you can also use the storewide link.