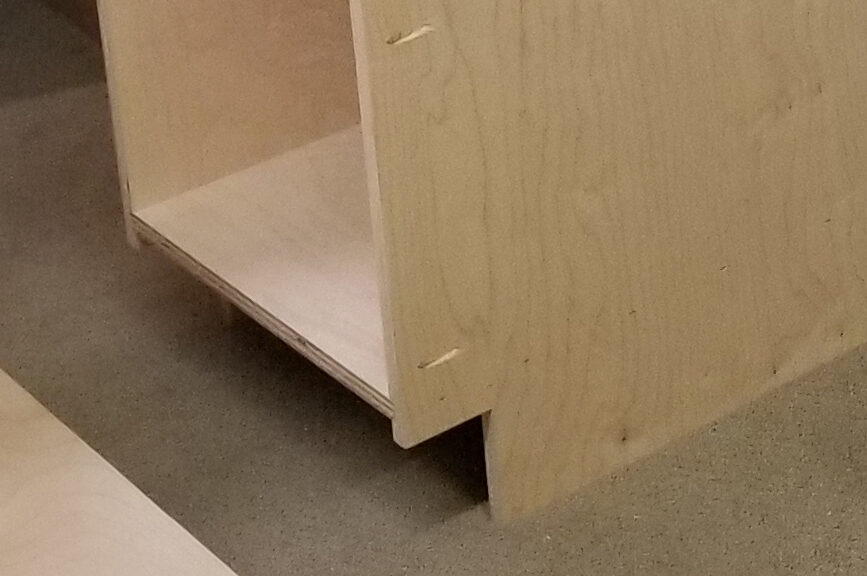

What is a toe kick? Look no further than the bottom of your base cabinet. It is cut out at the bottom of the base cabinet where your foot can slide under – or more likely, where your toes will not kick the cabinet.

So how do you cut them? You can cut them on a table saw, band saw, using a jigsaw, circular saw, or even by hand. For the purpose of this article, I’m going to focus on how I cut them using a table saw. While this method may not be the safest, yes, you heard that correct, I find that if you follow safe cutting guidelines by not trapping your workpiece between the fence and the blade, it can create a clean accurate cut.

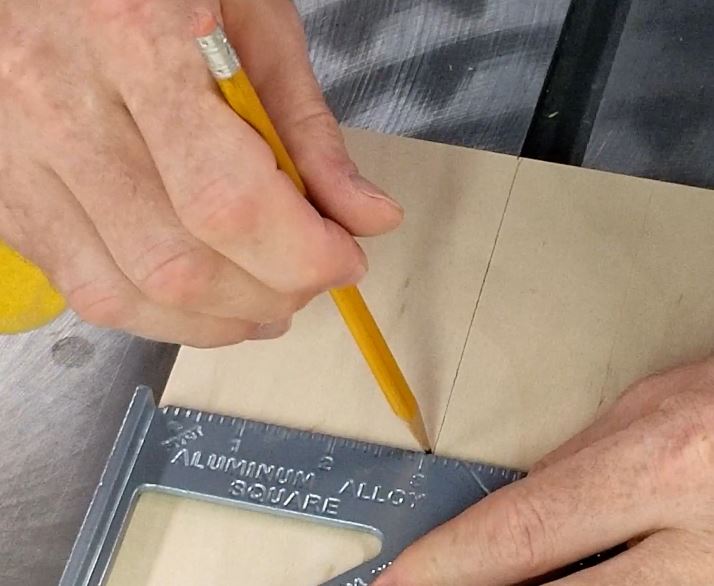

The first thing I do is diagram out where I’m going to cut on one of my base cabinet sides. This allows me to get an accurate cut for this first one. After that, I will use this one to trace onto all the other sides. Note you need to do this on the front side of your side panel. This is because if you cut a rabbit along the back for the back panel you don’t want to put the back upfront. You’ll also want to make sure you’re marking the bottom, after all, a toe kick on the back or top isn’t going too much good and will waste all the time and material you did on this one side so far.

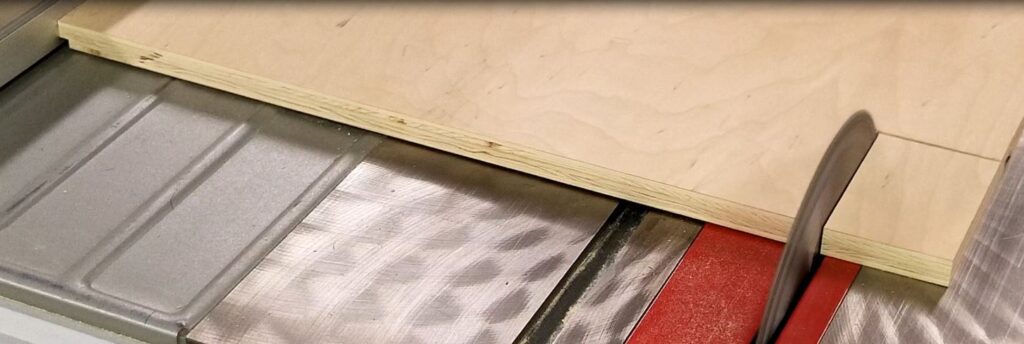

After tracing out where you’re going to cut – for me, this was 4 1/2″ high and 3″ deep you’ll need to figure out the cutting order a such a way that you do not trap the waste piece between the fence and the blade. If you do trap it this piece can fly back and hit you or anything resulting in serious injury. Depending on whether your cutting the left or right cabinet panel side depends on which side you’ll cut first.

As you can see from this picture for me, when looking at the cabinet, I’m cutting the left side and doing the horizontal cut first. Then after doing all the left side horizontal cuts, I’ll reposition the fence to do the vertical cut on the left sides.

With the blade raises as high as possible to create as much of a vertical cut as possible, place the work material side down and make your cut. This will allow the overcut from the saw to be hidden underneath the bottom and inside of the cabinet. It will not be visible from the outside.

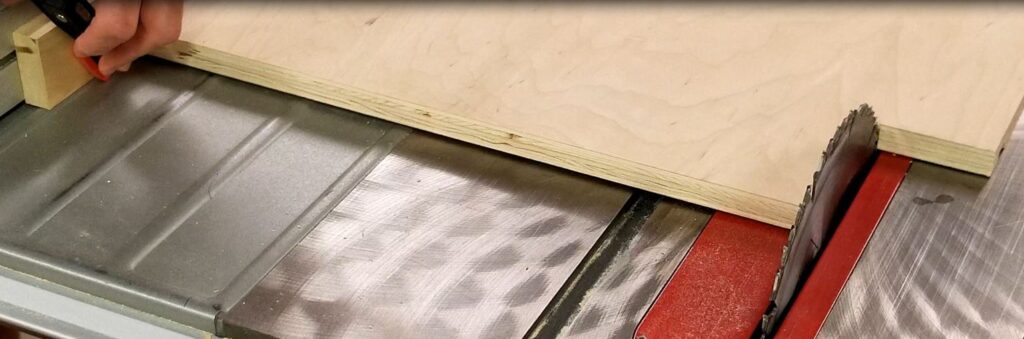

Once you’ve cut to the line you drew, turn the saw off. Never attempt to remove the piece with the saw still running as it may pinch the material causing a kickback. Once the saw stops, set up a stop block so you can cut the remaining sides that match this fence position.

After you finish cutting all those sides, reposition your fence to cut the vertical cut in such a way that the waste material will drop off and not be pinched by the panel and the blade.

Remember to add a stop block after cutting the first piece. Although, this may not be necessary if you’re paying close attention to when the piece drops off and stop pushing the material through the blade.

Since may saw can only cut one base cabinet side safely due to the size of my fence, I either have to freehand cut the other cabinet side or use my panel sled. Since I have a panel sled I’m going to use it. It will allow me to create accurate cuts. Again, I set up a stop block after cutting the first cut.

After cutting all the toe kicks I end up with a decent amount of toe kick block waste. I’m not sure what I’m going to do with these yet – aside from throwing them in my fireplace which I really hate to do.

As always if you have any questions or comments post them below or on my YouTube video comments section and I’ll do my best to respond.

I’ve included a few Amazon Links below for the equipment and materials I used.

Equipment and Materials

- Bessey LM2.004 LM General Purpose Clamp

- Bessey GSCC2.506 6″, Clutch StyleMedium Duty Clamp

- Walker’s Razor Slim Passive Earmuffs

- Bosch 10″ 50 Tooth PS1050

I hope you find this video useful and can use some of the tips presented. Feel free to leave any comments, suggestions, or experiences you have had below.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a different purchase from Amazon, you can also use the storewide link.