I’m really not going to write a full article on how to do this. Most of the information is contained within the YouTube video. You can watch it for details, but I wanted to make a mention that this is the latest and last installment of the Faux Mantel Build.

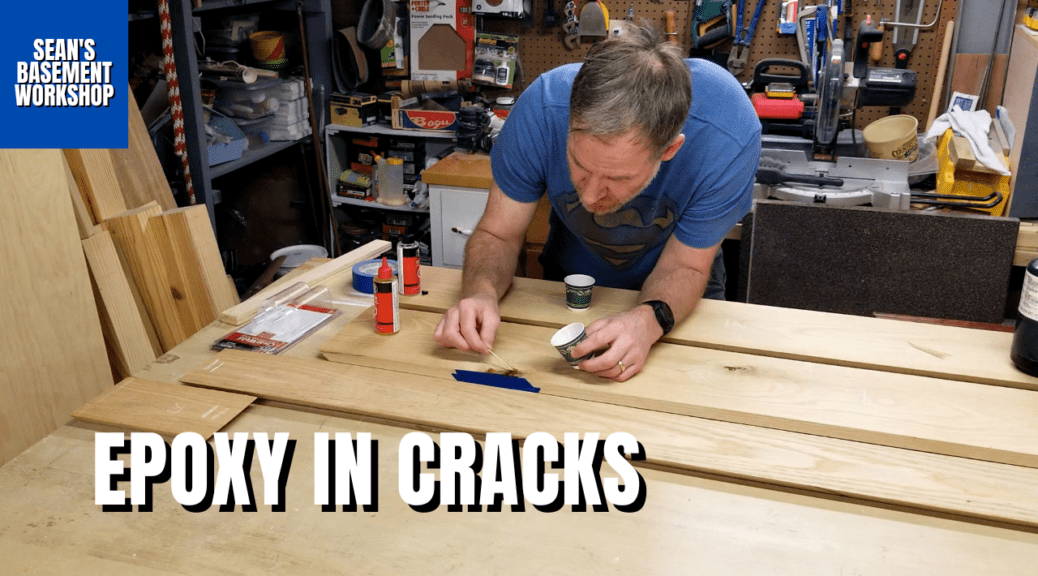

If you want me to expand on the details of how I used JB Weld Epoxy to fill the cracks and knot holes, heat to pop the bubbles, and dye to tint the epoxy, let me know below in a comment, and I’ll expand.

Head on over to YouTube by clicking on the video below and see how it was made and turned out.

I hope you find this helpful video useful and can use some of the tips presented. Feel free to leave any comments, suggestions, or experiences you have had below.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a purchase from Amazon, you can also use the storewide link.

Auto Amazon Links: No products found.