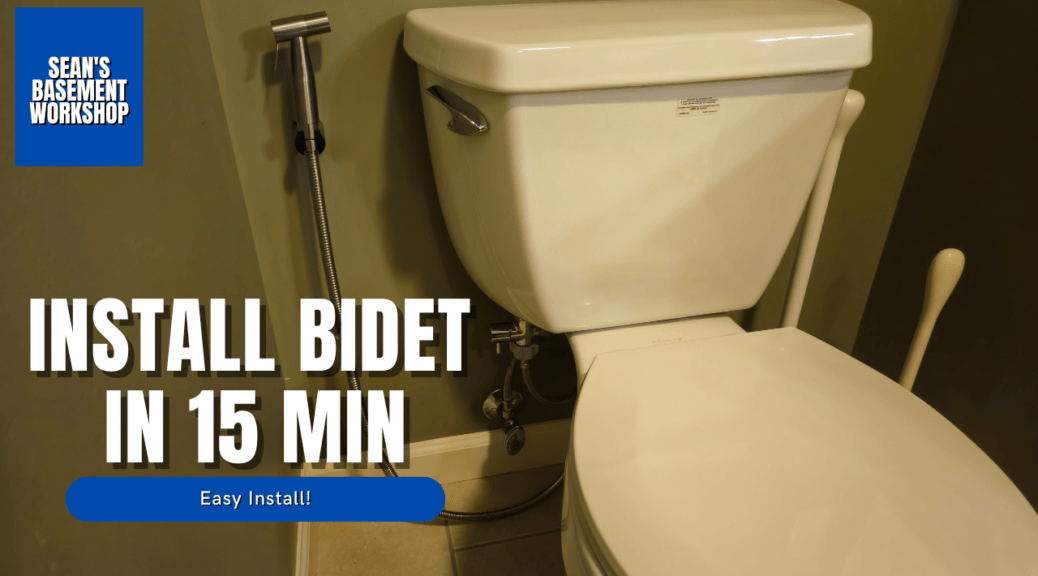

Ultimate Simple Guide to Install Handheld Bidet Sprayer (DIY Beginner Friendly)

If you’re looking for an affordable bathroom upgrade that improves hygiene and reduces toilet paper use, learning how to install handheld bidet sprayer is one of the smartest DIY projects you can tackle.

In this step-by-step guide, I’ll walk you through the entire installation process in a clear, beginner-friendly way. This project requires minimal tools, takes less than an hour, and can be completed by most homeowners — even if you’ve never done plumbing work before.

Be sure to watch the full video tutorial embedded below to follow along visually.

Table of Contents

Why Install a Handheld Bidet Sprayer?

A handheld bidet sprayer (sometimes called a diaper sprayer) connects to your existing toilet water supply and allows you to control water flow manually.

Benefits:

- Improved personal hygiene

- Reduces toilet paper use

- Eco-friendly

- Budget-friendly upgrade

- Easy to install and remove

- No permanent plumbing modifications required

- No permanent electrical modifications required

For DIY beginners, this is an excellent confidence-building project, unless you are afraid of the insides of a toilet tank!

Tools and Materials Needed

Before you install the handheld bidet sprayer, gather the following:

Tools:

- Adjustable wrench (or a wrench that fits on the nut on the shutoff valve – for me, that was a 5/8″ wrench).

- Small towel or rag

- Bucket or bowl (to catch excess water)

- Pliers

- Screwdriver

- Drill and an appropriately sized bit for a drywall screw anchor

Materials:

- Handheld bidet sprayer kit

- Flexible hose (if your existing one needs replacing)

No soldering, pipe cutting, or special plumbing tools required.

Important Safety Step Before You Begin

Before starting:

- Turn off the toilet water supply valve (located behind the toilet near the floor). You may need to work this back and forth to get it to close completely.

- Flush the toilet to empty the tank.

- Place the bowl and towel under the supply line to catch drips.

- Slowly disconnect the supply hose from the bottom of the tank. If the valve is not closed, you may experience some continued spraying.

You may see a small amount of water — this is normal.

Step-by-Step: How to Install Handheld Bidet Sprayer

Step 1: Remove the Existing Water Supply Line

Using your wrench or pliers if required:

- Loosen the nut connecting the water supply hose to the bottom of the toilet tank.

- Unscrew it by hand once loose.

- Leave the other end attached to the wall shutoff valve if you can reuse this line. I could not because mine was a hardline and needed to be removed.

You are only disconnecting the tank connection unless you have a hardline.

Step 2: Install the T-Valve

The T-valve is the key component that splits the water supply between the toilet tank and the sprayer.

- Attach the T-valve to the bottom of the toilet tank where the supply line was connected, making sure there is a rubber seal in the connection.

- Hand-tighten first.

- Use your wrench to snug it slightly — do not overtighten. All you need to do is not leak.

Overtightening can damage threads, crush washers, or even crack your tank!

Step 3: Reconnect the Toilet Supply Line

Now:

- Connect the original supply hose to the bottom of the T-valve. If you had a hardline, now is when you’ll need to remove use a replacement flex line like I had to.

- Hand-tighten.

- Snug gently with a wrench.

Your toilet tank connection is now restored.

Step 4: Attach the Bidet Hose

Next:

- Connect one end of the flexible bidet hose to the side outlet of the T-valve.

- Hand-tighten only (most kits use rubber washers and do not require wrench tightening).

Then:

- Connect the other end of the hose to the handheld sprayer.

Again, hand-tighten securely.

Step 5: Mount the Sprayer Holder

Most kits offer two mounting options:

Option 1: Tank Mount Bracket (Easiest for Beginners)

- Remove the toilet tank lid if you haven’t already.

- Slide the mounting bracket into position.

- Replace the toilet tank lid.

I was unable to use the tank-type mount because my lid would not fit back on with it, so I had to use the Wall Mount.

Option 2: Wall Mount

If choosing a wall mount:

- Locate a suitable location for mounting it. Make sure it is easy to reach in order to use.

- Mark mounting holes.

- Drill pilot holes.

- Use anchors if mounting to drywall; otherwise, the screws can pull out.

For beginners, tank mounting is simpler and requires no drilling.

Step 6: Turn Water Back On and Check for Leaks

Now the important part:

- Slowly turn the water shutoff valve back on.

- Watch all connection points.

- Look for drips at:

- Tank connection

- T-valve threads

- Hose fittings

If you see a drip:

- Tighten slightly.

- Do not overtighten.

Let the tank fill fully before testing the sprayer.

Step 7: Test the Sprayer Carefully

Hold the sprayer over the toilet bowl and gently squeeze the trigger.

Start slowly.

Water pressure may be stronger than expected.

Check all fittings again while spraying to ensure no leaks develop under pressure.

Common Beginner Mistakes to Avoid

When you install handheld bidet sprayer, these are the most common issues:

1. Overtightening Connections

This can damage rubber washers, crack the tank, and/or cause leaks.

2. Forgetting to Turn Off Water First

Always shut off the supply before disconnecting lines.

3. Not Checking Washer Placement

Every connection should have a rubber washer inside.

4. Leaving Sprayer Pressurized

When not in use:

- Turn off the shutoff valve if recommended by the manufacturer.

Some homeowners prefer shutting off the water to the sprayer after each use for extra safety.

Water Pressure Tips

If your water pressure feels too strong:

- Open the shutoff valve partially instead of fully.

- Use a pressure control valve if needed.

- Never modify internal sprayer components.

Most kits are designed to operate on standard residential pressure safely.

Maintenance and Care

To keep your bidet sprayer working properly:

- Periodically check for leaks.

- Inspect the hose annually.

- Replace washers if dripping develops.

- Avoid dropping the sprayer.

This is a low-maintenance upgrade that can last years.

Is This Project Renters-Friendly?

Yes.

If you’re renting:

- Installation is reversible.

- No permanent modifications required.

- Simply remove T-valve and reconnect the original hose when moving out.

Always confirm with the landlord if required.

How This Upgrade Saves Money

Installing a handheld bidet sprayer can:

- Reduce toilet paper usage significantly

- Lower long-term bathroom supply costs

- Improve hygiene without an expensive remodel

It’s one of the most affordable bathroom upgrades available.

Why This Is a Great DIY Starter Project

If you’re new to DIY:

- No cutting pipes

- No electrical work

- No specialty tools

- Low risk

- High reward

This project builds plumbing confidence and prepares you for future bathroom upgrades.

Other Bathroom Projects

- If your toilet keeps running because the flapper inside is worn out, check out the Quick Toilet Flapper Replacement article.

- Loose towel rod in your bathroom? I have you covered here Fix a Loose Towel Bar

Conclusion

Learning how to install handheld bidet sprayer is one of the easiest and most practical upgrades you can make in your bathroom.

It’s affordable, beginner-friendly, and requires only basic tools. With careful installation and proper leak checks, this project can be completed in under an hour.

If this guide helped you, be sure to:

- Watch the full video tutorial

- Subscribe on YouTube

- Leave a comment with your questions

- Share this article with other DIY homeowners

More simple DIY projects are coming soon.

Frequently Asked Questions

Q: Is it hard to install handheld bidet sprayer?

A: No. Most beginners can complete installation in under an hour using basic tools like an adjustable wrench.

Q: Do I need a plumber to install a handheld bidet sprayer?

A: In most cases, no. The installation connects to the existing toilet supply line without permanent plumbing modifications.

Q: Will installing a bidet sprayer cause leaks?

A: If properly tightened and the washers are seated correctly, leaks are unlikely. Always check connections after turning water back on.

Q: Can renters install a handheld bidet sprayer?

A: Yes. The installation is reversible and does not require permanent changes.

Q: Does a handheld bidet sprayer affect toilet performance?

A: No. The T-valve splits the water supply but does not reduce the normal tank function when installed correctly.

Watch the Full Installation Video

For a complete visual walkthrough of how to install handheld bidet sprayer, watch the full tutorial on my YouTube channel.

The video shows:

- Real-time installation

- Leak testing

- Mounting demonstration

- Beginner-friendly pacing

👉 If you found this helpful, subscribe to the channel for more simple DIY home improvement projects.

You can also help support my Channel at Buy Me A Coffee.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a purchase from Amazon, you can also use the storewide link.