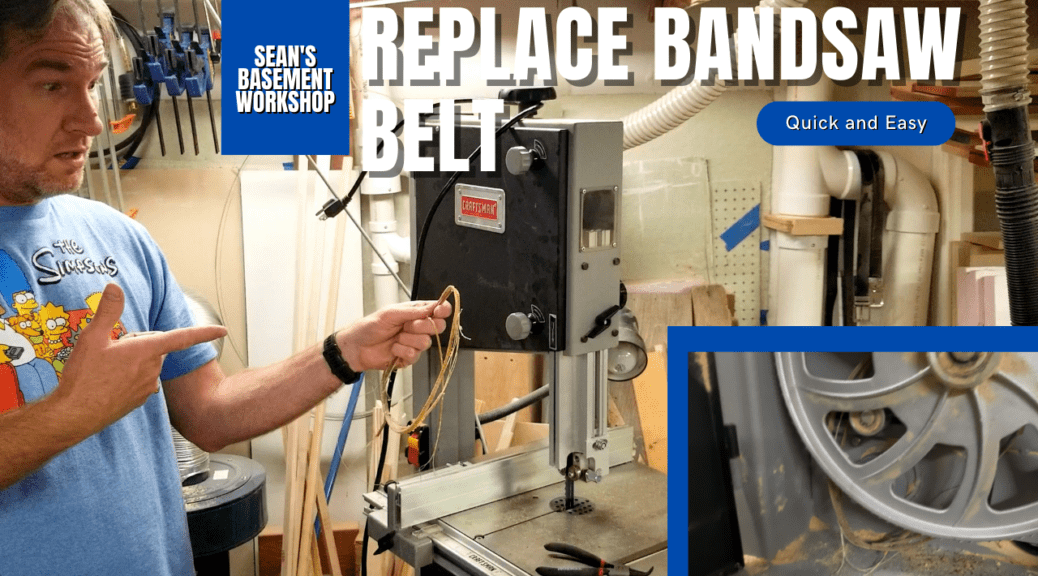

Is there anything worse than working on a project and you flip the power on one of your power tools that does not operate as expected? Well, that is what happened to me when I went to use my bandsaw. The motor kicked on but that bandsaw blade didn’t spin. Opening up the bottom cover where the drive wheel was quickly told me what was wrong – the drive belt had shredded itself.

That’s right! After years of use and aging the clear nylon belt had completely broke and resembled strings as this belt was a multi-ribbed belt that basically broke and shredded.

I took the model number for my bandsaw and quickly found a twin pack of replacement belts on Amazon. I was thrilled because it was less expensive than a single replacement from Sears’s Parts store. I ordered and the belt arrived within days.

You’ll find below the steps I took to replace this belt. It was pretty easy to do and didn’t take much time to complete allowing me to get my saw up and running in less than 30 minutes.

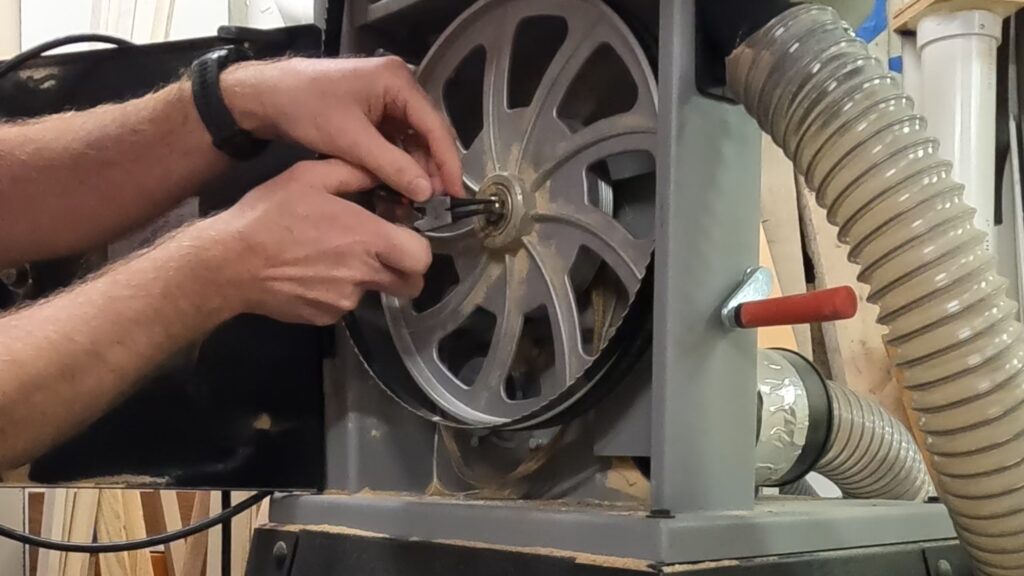

I gathered up the tools and supplies I needed. This was simply a snap ring plier and a new multi-ribbed belt.

Next, I unplugged the bandsaw and removed the tension from the drive wheel as I needed to remove the blade from the drive wheel. I opened up the lower access door and worked the blade off.

In order to slide the drive wheel off the axle I needed to remove the snap ring. I set the ring aside along with the snap ring plier on the tabletop so I wouldn’t lose them.

I slide the drive wheel off and you can truly see the carnage the belt was showing. I pulled it off and while I had everything all open I decided this was a good time to blow all the dust out with compressed air.

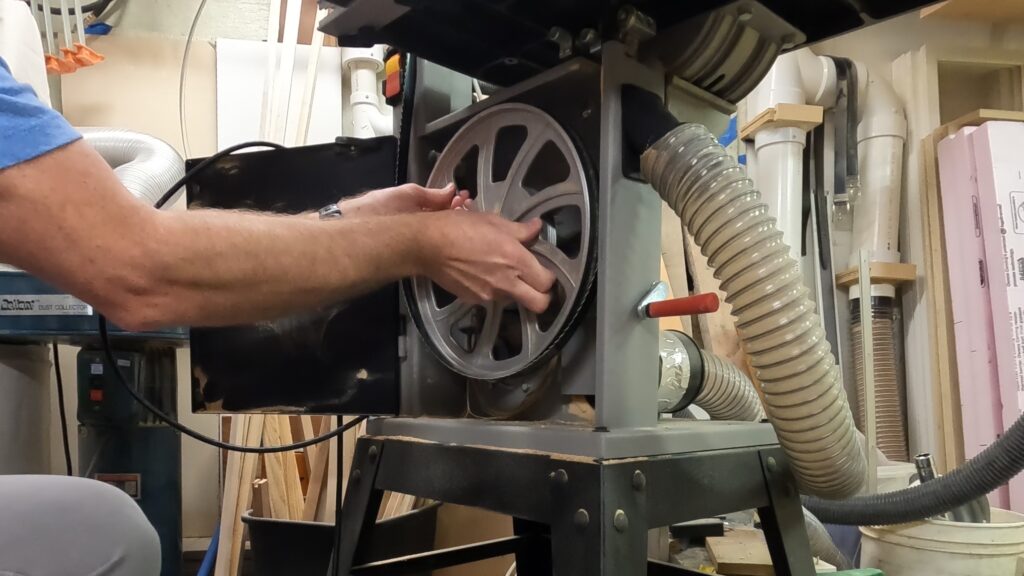

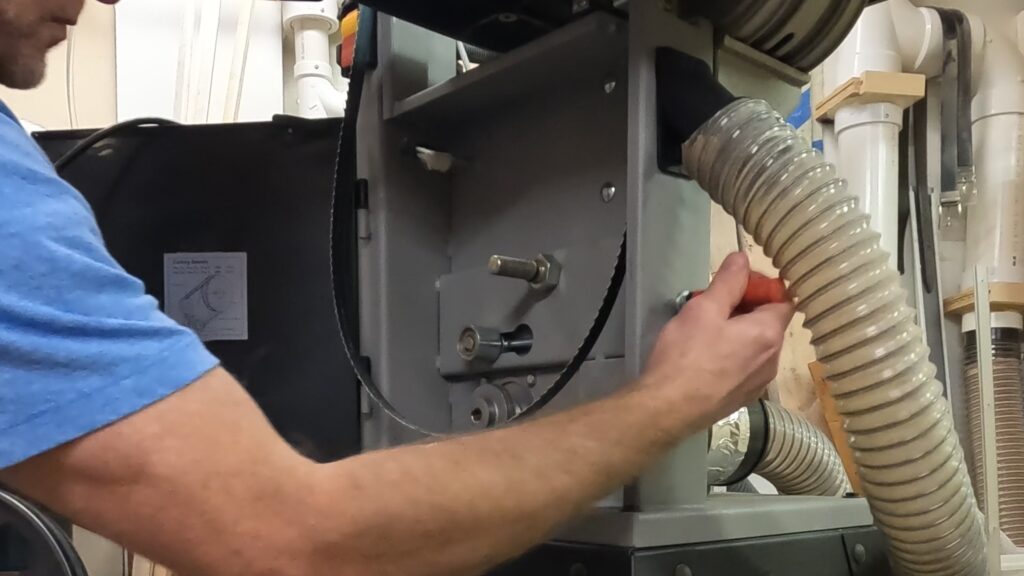

After everything was clean I reduced the belt tension so I could get the new belt over the drive wheel pulley, the motor, and the tensioner pulley. Sliding all this back on at once became a bit of a challenge as the belt kept wanting to slide off the drive-wheel pulley.

Once I had the belt routed properly again I tensioned up the belt snugly so it would not slip but not too tight. I reattached the snap ring to the drive wheel axle and worked the bandsaw blade back on the drive wheel.

After that was done I put the blade under some tension and hand spun it to ensure it was going to ride in the center of the wheels. I had to adjust this a couple of times but was satisfied overall. I closed up the access doors, plugged the unit back in, and turned it on briefly to ensure the blade was not going to wander from the center of the wheels.

This completed the belt change out and got me back in business using my bandsaw.

As always if you have any questions or comments post them below or on my YouTube video comments section and I’ll do my best to respond.

I’ve included a few Amazon Links below for the equipment and materials I used. By clicking on any of the links in this article you help support my channel as I earn from qualifying purchases.

You can also help support my Channel by dropping a Tip at https://withkoji.com/@sean.moenkhoff

Equipment and Materials

*Disclaimer: While I attempt to list the equipment I use, some items have been discontinued or have newer models.

I hope you find this helpful video useful and can use some of the tips presented. Feel free to leave any comments, suggestions, or experiences you have had below.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a different purchase from Amazon, you can also use the storewide link.

![3-Pack [3.3FT+6.6FT+10FT] 60W USB C to USB C Cable, Type C to Type C Cable,Fast Charging Cable Compatible with iPhone 15/Plus/15 Pro/Pro Max,Samsung Galaxy S23 S22, iPad Pro, MacBook Air and More #1](https://m.media-amazon.com/images/I/51t4OI9I6gL._SL100_.jpg)

![3-Pack [3.3FT+6.6FT+10FT] 60W USB C to USB C Cable, Type C to Type C Cable,Fast Charging Cable Compatible with iPhone 15/Plus/15 Pro/Pro Max,Samsung Galaxy S23 S22, iPad Pro, MacBook Air and More #2](https://m.media-amazon.com/images/I/51V9TR8X+lL._SL100_.jpg)

![3-Pack [3.3FT+6.6FT+10FT] 60W USB C to USB C Cable, Type C to Type C Cable,Fast Charging Cable Compatible with iPhone 15/Plus/15 Pro/Pro Max,Samsung Galaxy S23 S22, iPad Pro, MacBook Air and More #3](https://m.media-amazon.com/images/I/51El9De5MJL._SL100_.jpg)

![3-Pack [3.3FT+6.6FT+10FT] 60W USB C to USB C Cable, Type C to Type C Cable,Fast Charging Cable Compatible with iPhone 15/Plus/15 Pro/Pro Max,Samsung Galaxy S23 S22, iPad Pro, MacBook Air and More #4](https://m.media-amazon.com/images/I/51K8iO5mT6L._SL100_.jpg)

![3-Pack [3.3FT+6.6FT+10FT] 60W USB C to USB C Cable, Type C to Type C Cable,Fast Charging Cable Compatible with iPhone 15/Plus/15 Pro/Pro Max,Samsung Galaxy S23 S22, iPad Pro, MacBook Air and More #5](https://m.media-amazon.com/images/I/51plYVoPewL._SL100_.jpg)