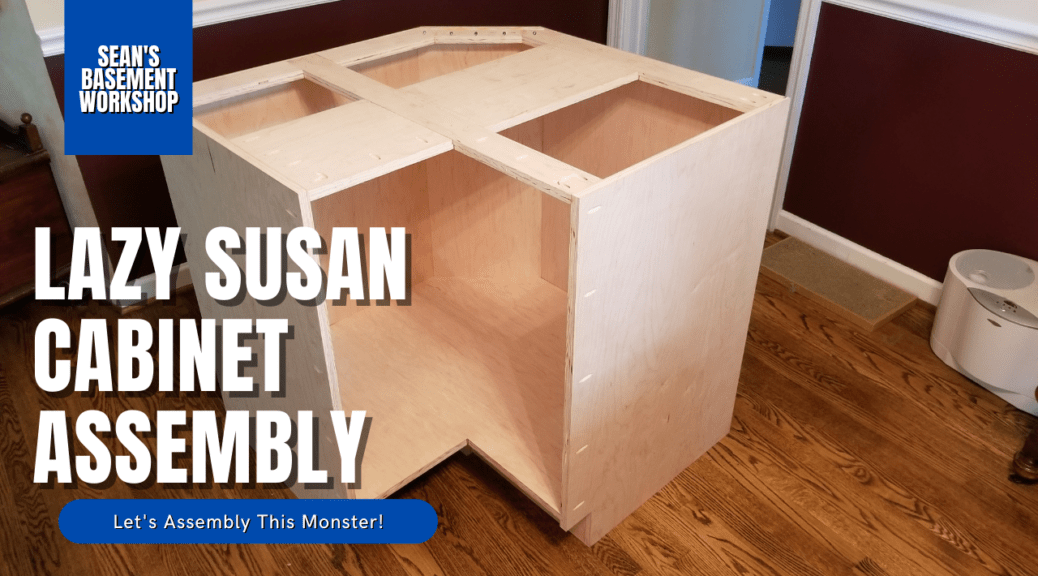

The time has finally come to assembly this monster of a cabinet. I’m talking about the Lazy Susan / Base Corner Cabinet. From the previous article, if you remember right, this cabinet is 36″x36″x34 1/2″ in size. Since my shop is in my basement and I only have standard 32″ doors I cannot assemble it in there. If I did and believe you me, I would have to take it apart to get it out of there. Yes, I’ve made that mistake before with a large bookshelf cabinet I made. The combination of it being too long and too high would not allow me to get it up the stairs.

So, I’ll be assembling this cabinet in my dining room, which will be a staging area for our kitchen remodel anyway. To keep my air compressor noise down I’m just going to run the air hose up through my laundry chute and use it that way.

I start by laying out all the components so I ensure I have them all. Once that is complete I start with attaching the side panels to the bottom shelf panel. I do this using Titebond II glue along with 1 1/2“ crown staples using my Bostitch 18 gauge stapler. The glue providing the chemical bond and the staple providing the mechanical bond is plenty of strength to hold these together when complete.

Once I get both sides stapled on I flip the cabinet over so it’s bottom-up. From this point of view, I add the back 45-degree panel using glue and pocket screws. I could have stapled and glued this like I did the sides but since the back did not have a dado cut into it for the shelf to rest on I decided I wanted the pocket screws to provide extra verticle holding strength. I adjust the height using a spacer block cut the same height as the part of the sides below the shelf. This will provide the proper height needed for the back 45-degree panel.

Once I get done attaching the that I move onto adding the floor supports. This is nothing more than a piece of plywood cut to the same height as the spacer block used for the 45-degree panel. This extra support will prevent the cabinet floor from sagging over time. You may have noticed that in some cabinets, especially very long ones, the floor will begin to sag over time. this extra block support prevents that. In addition because of the way I positioned, it will allow for the toe kick to be nailed into it. This piece is attached using glue, staples to the side, and pocket screws to the bottom panel. Just ensure your screws are the right length so you do not go through the bottom. If you’re not using pocket screws you can also toenail the piece into the bottom but again, make sure you’re using proper length nails or staples to prevent them from going through the bottom.

Now I flip the cabinet carcass back over so it’s right side up. The next step is to add the top stretchers. This allows the top to become structurally sound and provides a means to attach Lazy Susan hardware to the top if you so desire. I will not be doing that as I’m going to add two adjustable half shelves.

I cut all the top stretchers so they have dados to provide half-lap joints. Between using glue and pocket screws to attach them and the sides, I also use 1/2″ crown staples for the half-lap joints. Assembly can be tricky for one person if you do not have three hands, clamps, or supports. So, if this is the case I recommend using another person to help here. Once assembled this framework structure is strong enough to lift the cabinet up.

Next, I flip the cabinet carcass over on one side to test fit the 1/4″ back panel. This panel runs between the 45-degree panel and the side panel. After determining it’s of the correct size I add glue to the rabbit and but joints and then use 1/2″ crown staples to staple it down. I follow the 3 corner method to ensure the cabinet is square before stapling the entire panel down.

I then repeat the process for the other back panel. In this view, you can see where my alignment of staples was off when attaching one side. Don’t worry, in the video below you can see where I went through and ran another line of staples just above. Sometimes this happens and fortunately for me, the missed staples were below the bottom of the cabinet floor so you will never see them.

Now, the only thing that is left is to attach the face frame. However, I’m not going to do that yet as I’m going to clear finish the cabinet and paint the frame white. To see how that’s done keep following the kitchen cabinet build articles.

Finally, I show how I predrilled the shelf pin holes except for the back 45-degree panel. This is because was easier to set the Rockler JIG IT Shelving Jig in and drill them after assembly rather than measuring and clamping the jig to the piece in the right position.

While assembling this cabinet carcass I did drop some sweat onto the cabinet. It’s important to resand these spots because the sweat will raise the grain and create a different finish appearance otherwise.

And for those who want some stats, the video below is a result of 20 videos totaling 55 minutes, 10 seconds edited down to 9 minutes, and 40 seconds. I can honestly say that I did not enjoy editing this as the program and computer I use started having problems keeping that many 4K files open at the same time.

As always if you have any questions or comments post them below or on my YouTube video comments section and I’ll do my best to respond.

I’ve included a few Amazon Links below for the equipment and materials I used.

Equipment and Materials

- BOSTITCH Crown Stapler, Narrow, 18GA

- DEWALT DPG94-1C Dominator SAFETY Glasses

- Estwing Deadhead Rubber Mallet DH-12 – 12 oz

- IRWIN QUICK-GRIP Bar Clamp, One-Handed, Medium-Duty, 12-Inch

- Kobalt 24-Volt Max Lithium Ion (Li-ion) 1/2-in Cordless Brushless Drill

- Kobalt 25-ft Tape Measure

- Kreg KHC-Premium Face Clamp

- Kreg Mini Kreg Jig Kit

- Kreg Pocket Hole Jig K4 Master System

- Kreg Right Angle Clamp

- Kreg SML-C125 Coarse Thread 1-1/4 Screws

- Maple (from a hardwood supplier)

- PONY 52 Pipe Clamp

- Rockler JIG IT Shelving Jig and 1/4″ Bit Set

- Ryobi BB0736 Corded Drill

- Staple, 7/32 In Crown, 1-1/2 In Long, Pk 3,000

- Staple, 7/32 In Crown, 1/2 In Long, Pk 7000

- Titebond II Glue

I hope you find this video useful and can use some of the tips presented. Feel free to leave any comments, suggestions, or experiences you have had below.

Some of the links in my video description and article above are Amazon Affiliate links. As an Amazon Associate, I earn from qualifying purchases. If you would like to make a different purchase from Amazon, you can also use the storewide link.